April/August 2017 – West Park & Friesland Sports Centres move to LED to improve lighting and reduce costs

LER recently completed the retrofit of 400w Sodium lamps to 100w low-energy LED Sports Lighting at West Park Sports Hall in Long Eaton (www.erewash.gov.uk)

The customer commissioned LER to design and install the new low-energy lighting in order to improve light levels and reduce energy bills by over 50%.

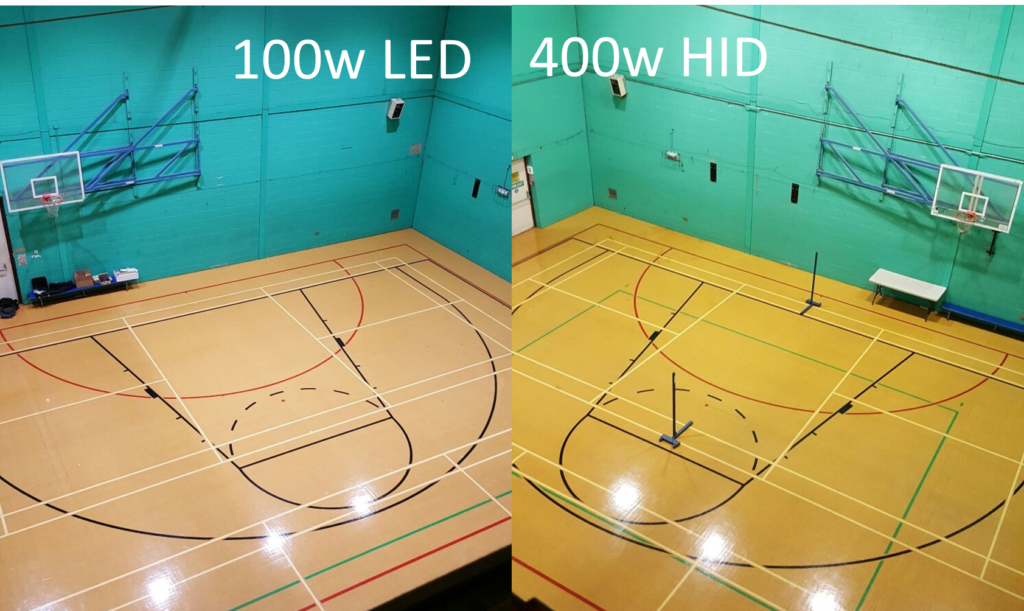

LER removed the old, yellowing sodium lamps and fitted new modern design LED floods at a height of 8m.

Lumens levels have been dramatically increased as can be seen on the adjacent picture, and anticipated annual electricity savings are expected to be in excess of £1500.

Coupled with the introduction of PIR’s sensors in goods in and despatch, the customer expects the project to pay for itself within 3 years – and the midi-bay lamps are guaranteed for 30,000 hours!

We had a slight issues with the PIR’s operating intermittently due to the close proximity of ceiling-mounted gas heaters. LER asked the local lighting manufacturer to accompany us to visit the customer to adjust the PIR sensitivity to compensate for this – whilst recognising when a member of staff came within 5 metres of any of the lights fitted with PIR. The lights are programmed to be turned off after 5 minutes without detecting activity, producing further energy savings.

The customer, who predominantly prints on metal foil for the pharmaceutical industry, is naturally delighted with the new lighting system and has now asked LER to fit a number of low-energy LED floodlights around the exterior of the factory in place of power-hungry unreliable halogens!